AIROTECH ENVIRONMENTAL

Turnkey Conversions / Up-Grades

Turn-Key Dust Collector Solutions

Thinking about up-grading or converting your existing dust collector?

Airotech Environmental has the experience, expertise and personnel for turnkey responsibility.

COSTS

Initial cost is often half the cost of a new unit. Saving the cost of new foundations, support steel, sidewalls,hoppers and dust removal systems.

PERFORMANCE

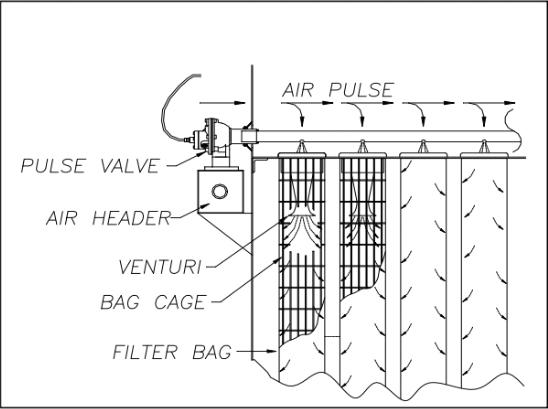

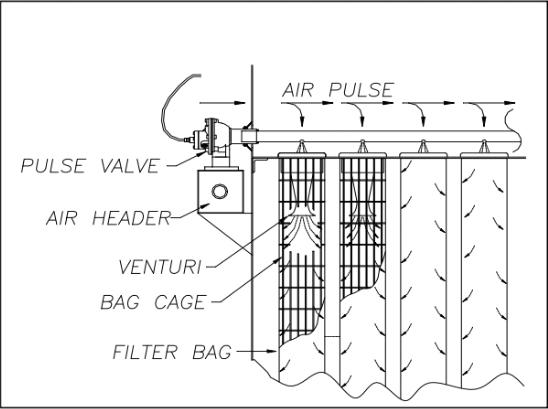

The Airo-Pulse™ cleaning system is more effective and efficient than shaker or reverse air cleaning systems and is designed to clean the filters while operating “on-line”.

SYSTEM VOLUME

The efficiency of the design as well as being able to clean“on-line”, the system volume is often double that of existing shaker or reverse air designs.

MAINTENANCE

The Airo-Pulse™ design has virtually no moving parts, thus substantially less maintenance is required. Leak detection is enhanced and bag access and installation are much easier.

Starting Demolition

Finishing Demolition

Lifting Modules from Truck

Setting New Module on Existing Hopper

Installing New Outlet Duct

Finished Installation

FEATURING

Welded Modular Construction

10 Gauge A569 Steel Housing Stiffened ± 20"

3/16” A36 Plate Tube-Sheet

6” Dia. Bag Type Or Pleated Element Filter

No Clamps Or Tools Required For Filter Change

11 Gauge Filter Cage With Integral Venturi (Bag)

Digital Timer For Filter Cleaning

1½” Controlled Air Consumption Pulse Valves

1½” Schedule 40 Manifold Pipes

Quick Opening Hinged Roof Doors

REPLACE EXISTING

Shaker Type Designs

Reverse Air Type Designs

Antiquated Pulse Designs

Pulse Jet Cleaning System Up-Grade

Is your dust collector suffering from…

High Differential Pressure ?

Poor Filter Life ?

High Compressed Air Usage ?

Reduced Process Ventilation ?

Then you need an upgrade!

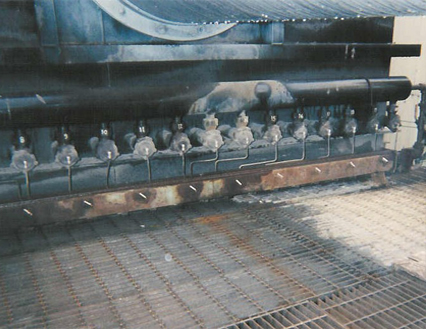

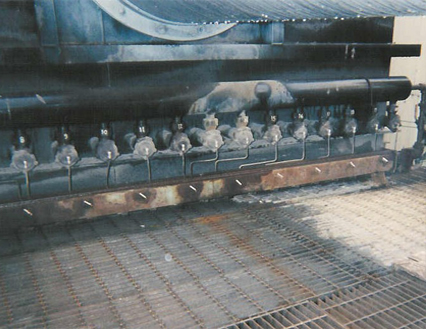

Existing Cleaning System (Coke Plant)

Airotech Environmental can upgrade most baghouse cleaning systems with the latest technology in pulse valve design. Even if your system is new, it may be equipped with antiquated pulse cleaning valves. Many dust collector manufacturers are still utilizing pulse valves that are technologically obsolete. Mainly because tens of thousands of dollars in tooling was purchased to cast there names onto the valves to differentiate their product as well as require purchasing only their replacement parts.

Features

The Airotech cleaning system utilizes high quality 1” -1½” controlled air consumption pulse valves that yield efficient, high performance. Coupling these valves to manifold pipes and a digital timer assures maximum efficient cleaning of the filtration media.

New Jet Pulse System After Upgrade

100% Satisfaction Guarantee

Call Us For A Free Estimate

352-729-4807