AIROTECH ENVIRONMENTAL

Gas Scrubbers and Absorbers

General Arrangements

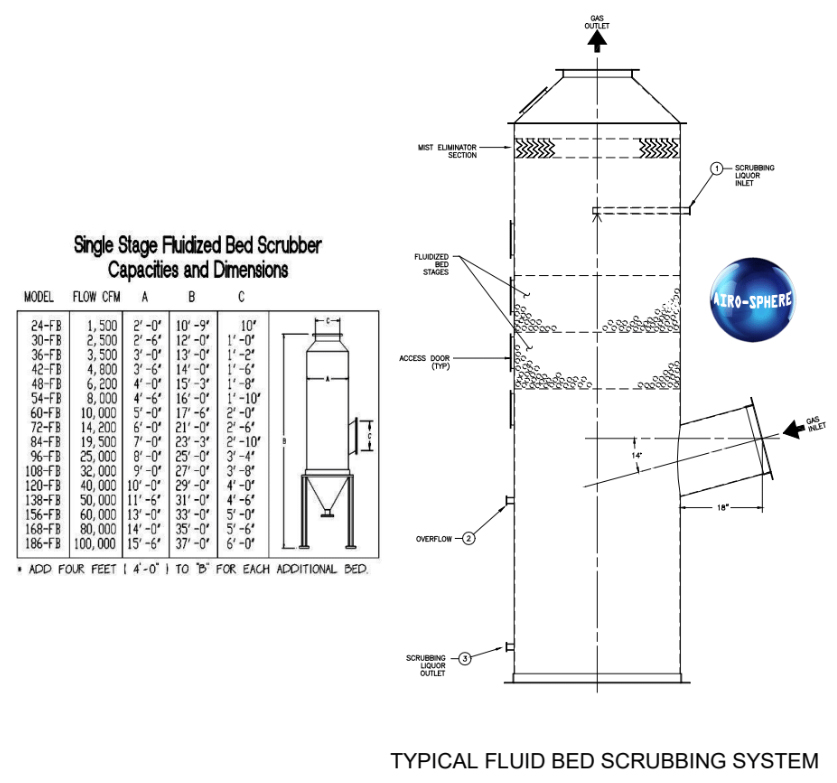

1,500 ACFM to 100,000 ACFM

Airo-ScrubberFluidized Bed Technology

Fluidized Bed Technology

The Airotech Airo-Scrubber™contains beds of low density Airo-Spheres™. These spheres are free to fluidize between internal upper and lower retaining grids. Liquid is introduced by way of spray headers at the top of the vessel and travels downward.

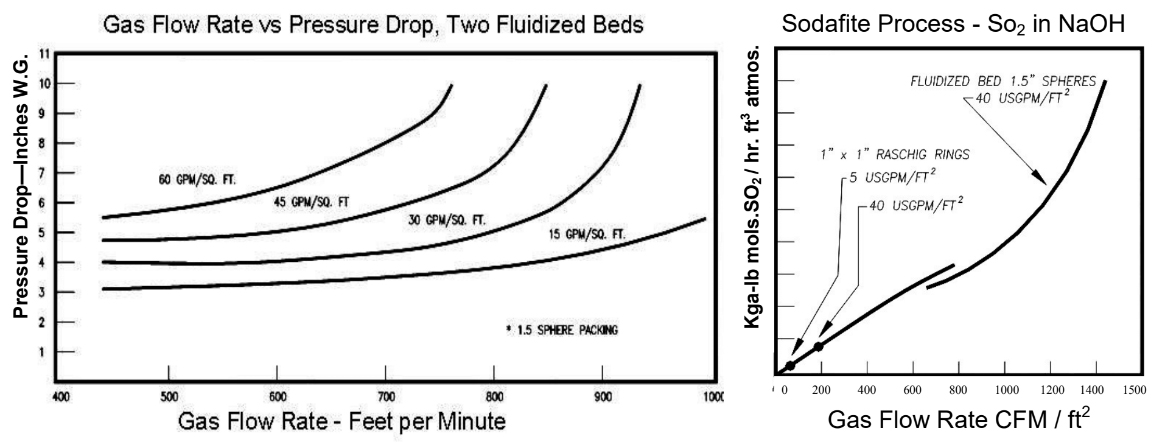

The gas to be reacted travels upward, countercurrent to the liquid flow. Gas velocities and liquid flow rates are maintained so that the sphere bed fluidizes, (elevates, agitates, rotates) in the gas stream. The fluidization permits high flow rates of both gas and liquid through the vessel. These high flow rates result in mass and heat transfer coefficients far in excess of those possible with conventional stationary packed designs.

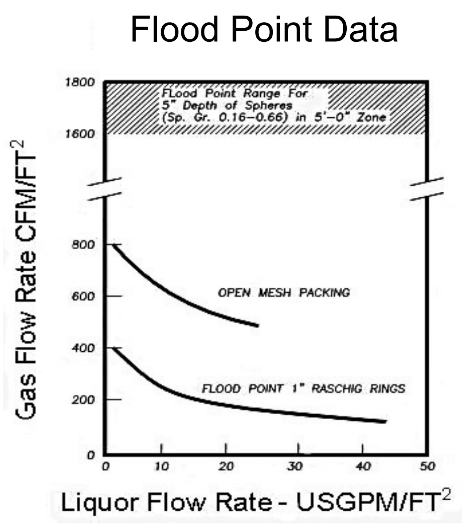

In typical counter current scrubber designs, a point is reached where gas upflow supports liquid downflow, a condition known as flooding. Flooding radically increases pressure drop, prevents countercurrent flow and effectively makes normal operation impossible.

Operational tests and installation data have proven that the Airo-Scrubber™ when packed with Airo-Spheres™ is capable of stable continuous operation at gas velocities ranging from 500 to 1300 feet per minute through the vessel at liquid flow rates up to 75 gpm per sq.ft. without reaching the critical point of flooding.

Features

High absorption of soluble gases due to theexceptional mass transfer characteristics of the fluidized bed.

Effective removal of dusts, tars, oils, andsuspended particulate without plugging orchanneling.

High gas and liquid throughput.

Low pressure operation at high masstransfer rates.

Wide operationl range without affectingoperational characteristics.

Fluidized Bed Advantages

Increased Efficiency:

The fluidized bed of Airo-Spheres™ is 5 times higher in mass transfer coefficient than stationary packed designs. This is achieved by the drastic reduction of both gas and liquid side mass transfer resistance as a result of the very high localized pressure gradients.

Non-Fouling:

Higher gas velocities and liquid flow rates are maintained so that the Airo-Spheres™ in the bed fluidize in the gas stream. This constant agitation continuously removes any build-up from the Airo-Spheres™, while providing exceptionally through interphase contact of the liquid and gas.

Lower Pressure Drop Operation:

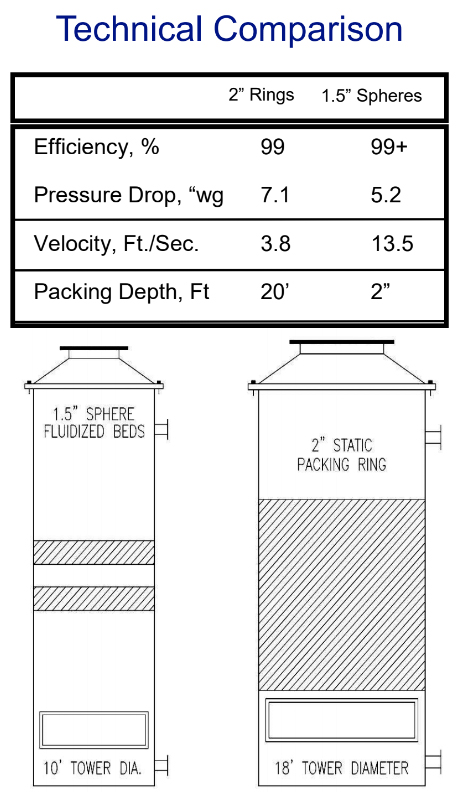

The Airo-Spheres™ in their fluidized state, as compared to 2” static ring packing, result in a 30% reduction in pressure drop in equivalent designs.Lower Operational Costs:Due to the lower operating pressure of the fluidized Airo-Spheres™, fan horsepower and electrical consumption can be reduced by as much as 33%.

Lower Packing Costs:

Two (2) one foot deep beds of Airo-Spheres™ are equivalent to almost twenty feet of static packing (based on 2” rings) while maintaining the same efficiency.

100% Satisfaction Guarantee

Call Us For A Free Estimate

352-729-4807